Our industrial heat pumps efficiently produce high-temperature heat in the form of water, steam or hot air from low-temperature heat sources.

Heat pumps for heating are more and more emerging as an enabling technology to reduce primary energy consumption and greenhouse gas emissions. They are the ecological and economically attractive solution to replace the conventional high-temperature heat generation systems.

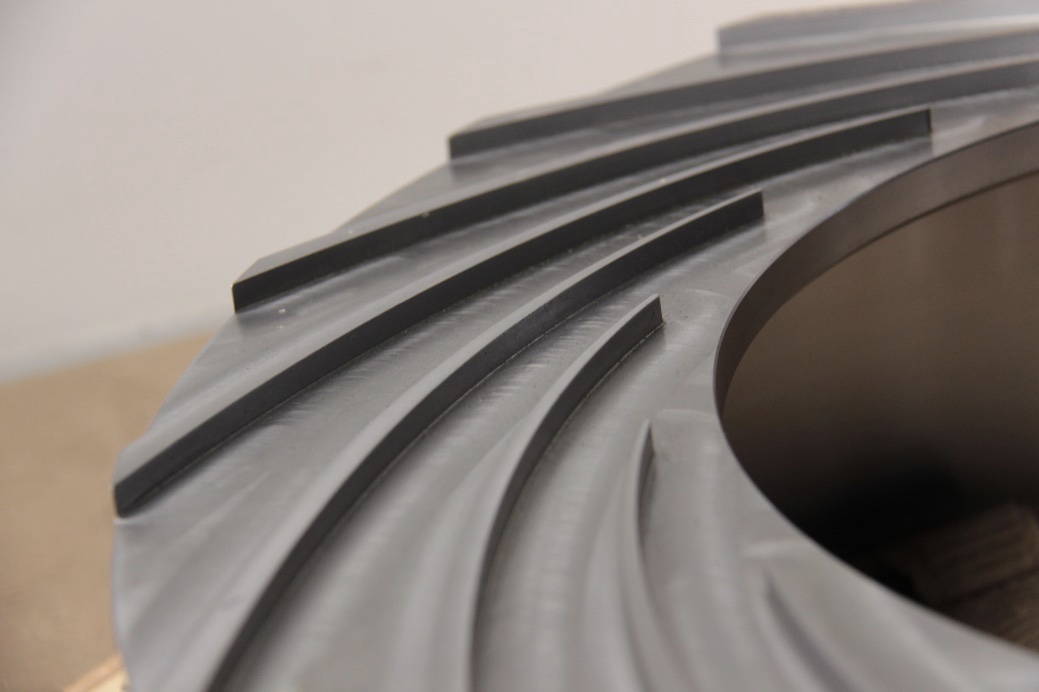

Thanks to its patented centrifugal compressor technology and proven know-how on heat pump systems, Enertime has recently developed high temperature industrial heat pumps to cover the high temperature heating needs of various industrial production processes in the food, beverage, paper, automotive and chemical sectors.

Designed to produce from 2500 kW to 15 MW of thermal energy per unit, high temperature heat pump design by Enertime are engineered to deliver optimum efficiency at very high temperatures. Given the highly specific needs of industrial sectors, each system is custom-designed and specially sized to meet high standards of efficiency and operational reliability.

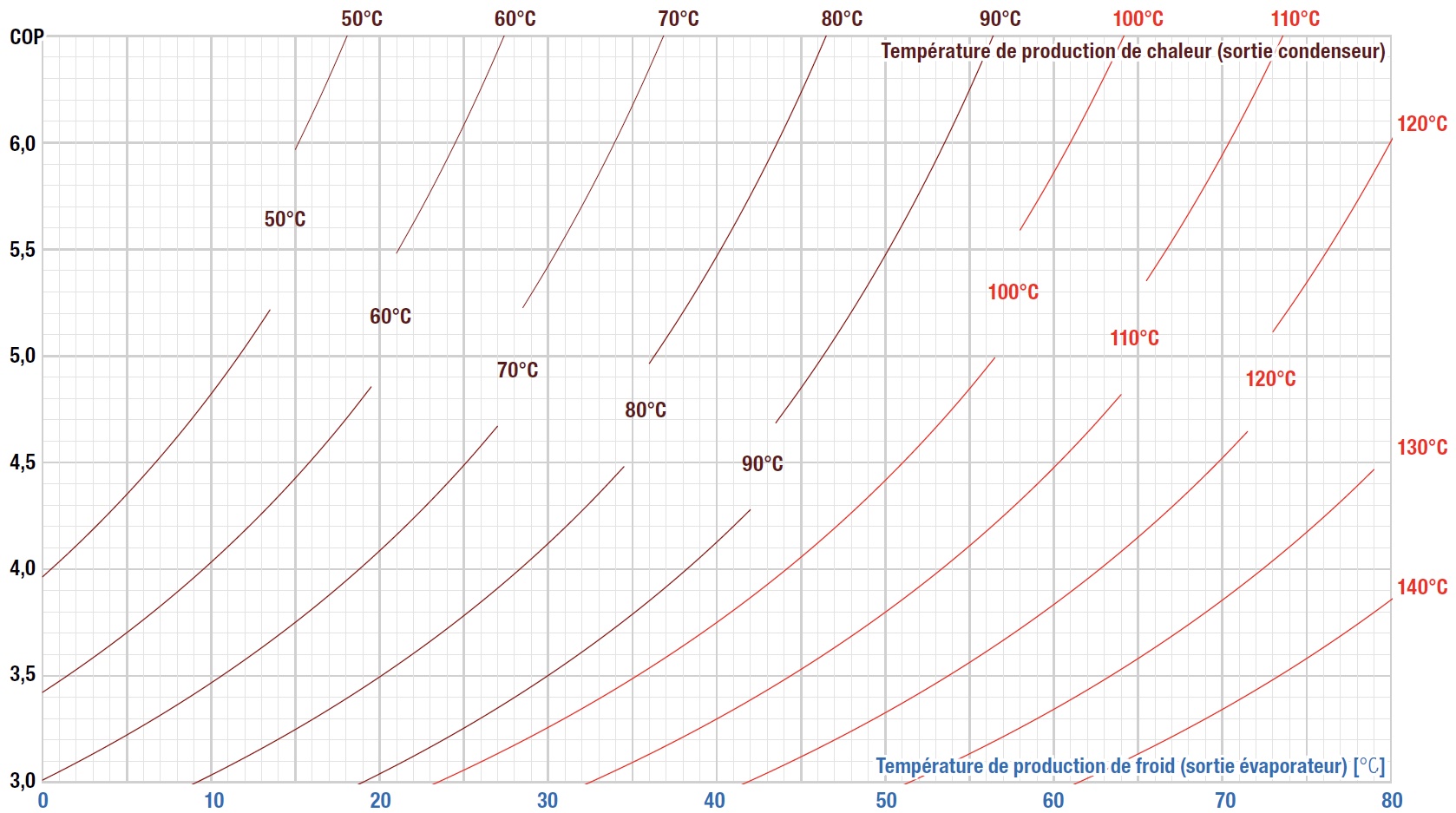

Performance curves for our heat pump system

Ranges and estimated COP

SPECIFICATION | HERMETIC MOTOCOMPRESSOR | OIL-LUBRIFICATED MOTOCOMPRESSOR |

Heat demand | 2.5 to 5 MWth | 5 to 15 MWth |

Working fluid | HFO, Alkanes | HFO, Alkanes |

Heat sink | 30 to 90°C | 30 to 90°C |

Heat production | >100°C | >100°C |

Motor size | Up to 1.8 MWe | 1 to 4 MWe |

COP | 2.5 to 6.0 | 2.5 to 6.0 |

Compressor | Single or two-stage centrifugal compressor (ENERTIME). 3 stages maximum, with the possibility of recompression beyond that. | Single or two-stage centrifugal compressor (ENERTIME). 3 stages maximum, with the possibility of recompression beyond that. |

Gearbox | - | YES |

Configuration | Compact unit with a small footprint | - |

The used fluids are new generation refrigerants (HFO) with an extremely low impact on the greenhouse effect (GWP < 5), and without affecting the ozone layer (ODP = 0). Non-flammable and non-toxic, they guarantee an easy and risk-free integration of our machines in the industrial and urban installations.

We also use alkanes in other applications to run our heat pumps at very high temperatures.

Leveraging our expertise in ORC modules, Enertime excels in developing customised heat pumps that directly generate steam or heat water, air or thermal oil for industrial applications. This unique capability comes from efficiently exploiting the significant synergies between our ORC products and our heat pump systems. We design solutions tailored to each need, enriched by our expertise in turbomachinery and heat exchanger sizing. In this way, we are confirming our commitment to the innovative and effective integration of our turbomachinery know-how into these systems, in order to precisely meet our customers' requirements.